|

|

|

PID Controller Auto-Tuning Software

BESTune

(For free demos go to section F. )

A. What Is BESTune?

BESTune is a computer program that provides best answers to the following frequently asked questions in industry:

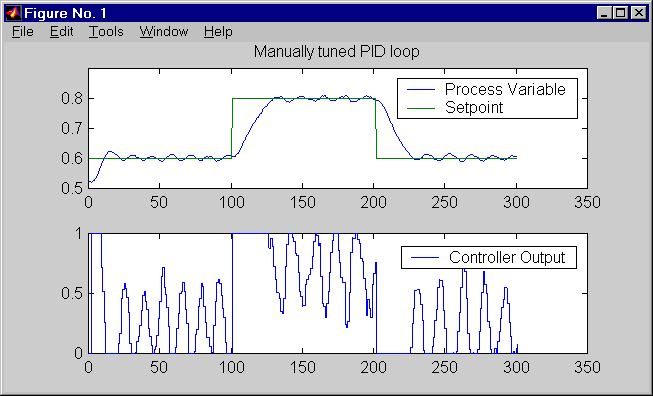

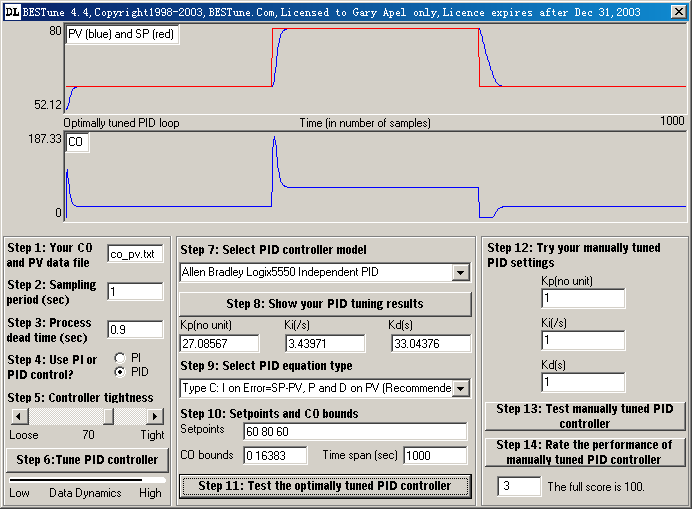

Here is an example. Suppose below is your manually tuned PID loop:

BESTune does the following:

Hardware and software requirements: Pentium compatible PC running Windows 95, 98, ME, NT4.0 or Windows 2000.

B. Important Features of BESTune

With our software BESTune, we guarantee your PID loops are optimally tuned. Important features of BESTune:

C. Success Stories From Industry

Story 1 is from a manufacturer of electromechanical machinery:

"This has been very interesting. Your program indicated I needed no Kd. Your

program came up with completely different Kp and Ki terms that settled 20 %

faster and with no oscillations...."

David Kerzel

Spraymation

5320 NW 35th Ave

Ft Lauderdale FL 33309

Story 2 is from a microcontroller manufacturer:

"I prepare a demo system today to understand and examine your BESTune. The demo system is a ventilator and air speed sensor. The ventilator speed is controlled by motor controller. I wrote a parallel PID for the system. I also added delays to the sensor by means of software and hardware filters to slow down the response of the system. I also wrote a program to transfer data to BESTune. Everything worked well! I tune the system and it worked almost excellent. I even did not make fine tuning..."

Han

Cizgi Ltd.

Turkey

Story 3 is from a leading dental product manufacturer:

A world class dental product manufacturer needs to burn ceramics

inside a furnace. To guarantee the quality of the products and the safety of the

production process, it is very important to accurately control the temperature.

Overshoot in temperature had been a major concern for a long time, which had

costed them a lot of time and effort. But with BESTune, they solved this

difficult problem within one day. See how their control engineer Mr. Lor~{(9~}nser

Johannes told his success story:

"Thank you very much for sending me the software! Today I tuned my

controller with BESTune 4.4 and it worked pretty well - there is no longer

overshoot in the temperature! BESTune is great! It is easy to use and saved us a

lot of time."

Johannes Lor~{(9~}nser

Control engineer

Story 4 The following opinion about BESTune was found on control.com's email news list on the internet:

"there are many ways to tune your PID ...etc but i can advice you to use a package called Bestune...it is so useful and i can help you if you can get a copy of that program."

Ibrahim A Fattah

Story 5 is from a BESTune user in academia:

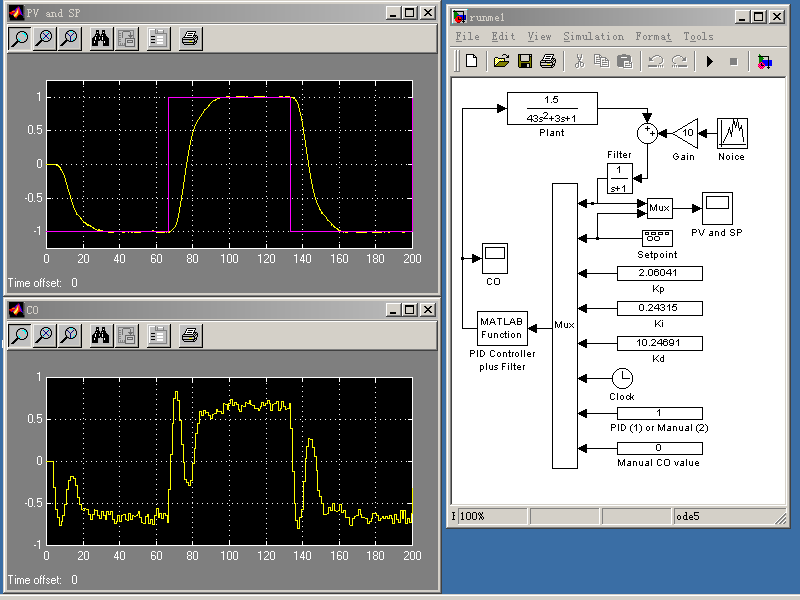

"Your BESTune is easy to use and makes my PID controller the way I want it to be.... I tried your BESTune on a demo engine speed control problem provided by the MathWorks in their product Matlab/Simulink. The performance of the PID controller tuned by your BESTune is even better than that of the MathWorks' PID controller...."

Ping

Story 6 Motor Speed Control

"I have to say this again: BESTune's control results are much better than those given by The MathWorks Inc. I applied BESTune to a motor speed control problem given in MathWorks' power system blockset. This is a simulated three-phase motor rated 1.1kW, 220V, 3000 rpm. I retuned the PID controller using your BESTune and I saw a significant improvement in the performance of the retuned PID controller compared with MathWorks' control result....And BESTune even suggested me a tighter PID controller settings..."

Ping

Story 7 More Success Stories From Academia.

Ping

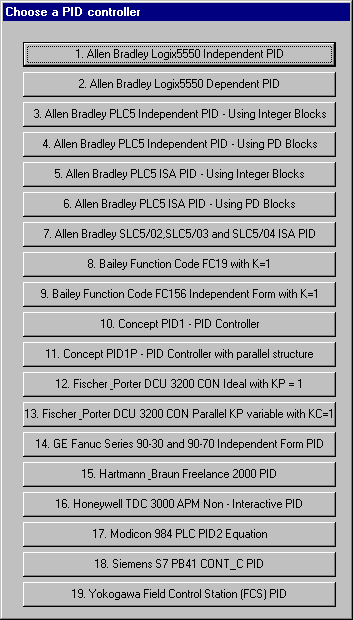

D. The PID Controller List in BESTune

E. BESTune Welcomes Challenges

Comparison shows difference. We encourage you to compare our BESTune with any other PID tuning software. For this purpose we provide an open contest on PID tuning so that you can try other PID tuning tools and compare with BESTune's results. We are quite confident that BESTune can beat any other PID tuning tools. You will find BESTune deserves its name!

Even better: Now it is easy for you to design your own PID loop with BESTune. The PID loop simulation software can automatically generate CO and PV data file. You just provide this data file to people with any PID loop tuning tools and ask them to return you the tuning results Kp, Ki, and Kd. Then you can use the PID loop simulation software to evaluate the tuning quality. Since you have full access to the source code of this PID loop simulation package, you can change the plant to any process you want to control. For more details take a look at http://bestune.50megs.com/piddesign.htm.

F. Free Demos

DEMO 1: (Newly updated) BESTune 4.4 Free demo.

DEMO 2: Success story 4 source code demo.

DEMO 3: Success story 5 source code demo.

DEMO 4: Success story 6 source code demo.

DEMO 5: Matlab and Simulink source code for evaluating various PID controller auto-tuning tools. For more details please visit http://bestune.50megs.com/piddesign.htm.

G. Price for Limited-Time Licensing of BESTune

H. Free Service Available

Before you purchase our BESTune, we encourage you to try our totally free service: Just email us your CO and PV data and we will give you the tuning results. Listed below are what you need to provide with us:

(1) Not less than 200-300 Measurements of CO (controller output) and PV (process variable). For the choice of the sampling period T please click here. Please note that these CO and PV data should show the dynamics of your process. Both CO and PV must be directly used by your PID equation. For exact definitions of CO, PV, and T visit this page or this page. This drawing shows where to find the CO and PV variables in a typical PID control loop.

(2) The sampling period T should be close to one half of the dead-time of your process, i.e., around (0.2 to 1)*(dead-time). If you are allowed to set up the sampling period Tpid used by your PID equation, please let Tpid=T, or Tpid is as close to T as possible. (Note: Tpid means every Tpid sec your PID equation updates it output CO once).

(3) The dead-time (also called time-delay, lag, response time, etc) of your process. It is the time period from the time when CO has a big step change to the time when PV begins to respond to this CO step change.

(4) Tell me what PID controller you are using. If it is not in BESTune's PID controller list, then please tell me the PID equation that is implemented in your PID controller.

We will retune you the tuning results. With BESTune, PID tuning is easy, quick, and fun. We enjoy tuning!

I. Multivariable MPC

Click here to see two real-time level and temperature control applications of multivariable model predictive controller designed by our company.

J. Contact Us

If you have any questions about our product and service, please feel free to email us at BESTune@gmail.com and/or visit us at http://bestune.50megs.com/. We will appreciate very much any of your comments and feedback.

L. Notes to Visitors

Thank you very much for visiting our web site. This is a newly designed web and will be under constant construction. New software will be available from time to time. Please visit here often.

For more details, go to http://justiceincanada.50megs.com/.

BESTune, Copyright (C) 2006, BESTune.Com (R). All rights reserved.